Timely maintenance of the equipment used in the mineral processing processes is very vital in order to have optimal performance of the equipment and also to help in the longevity of expensive equipment used in the mineral processing plants. Failure in the maintenance practices normally results in system breakdowns, high operational costs and reduced output. The paper aims to help B2B organizations which are involved in mining and mineral processing, with regards to the formulation of a proactive maintenance strategy that leads to enhanced efficiency, as well as cost reductions. In this article, Best Practices in Maintaining Mineral Processing Equipment as well as how these practices aid in sustenance of peak levels of performance will be discussed.

Inspection and monitoring of the equipment that are used in mineral processing are some of the most useful ways of maintaining the equipment. This practice helps operators to discover wear, malfunctioning or failure signs before these lead to costly breakdowns. Loose and often overlooked parts that should be inspected include motors, bearings, chutes, screens, liners, and all other parts of the plant that receive stress during its operation.

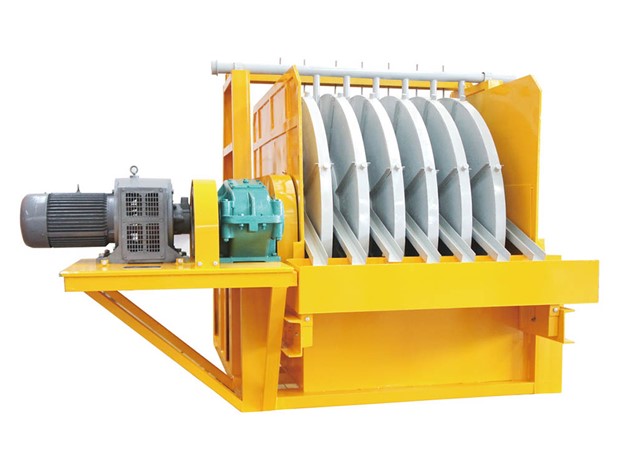

In the case of such equipment as magnetic disc separators Their efficiency depends on rather rigorous control of the magnetic field intensity and direction, and wear of the discs. Applications such as data from equipment sensors enables real-time determination of their condition hence when they require maintenance, thus helping in avoiding common breakdowns. Regular inspection of the business equipment also plays a very important role in reducing the probability of the equipment failing to function thus playing an important role of reducing losses that the business may be faced with.

In handling and operating mineral processing equipment, maintenance measures including supply of adequate lubricant, and cleaning form part of the basic practices that must be followed. Lubrication helps to minimize friction between the moving parts, and thus help in avoiding early failure of the equipment, while cleaning helps in removal of the dirt, dust and all other interferences which may affect their performance. Each practice is very essential in the enhancement of the life span of these machines.

Some of the examples are the crushers, grinders and magnetic disc separators; these require routine lubrication of moving parts. According to the recommendations of the manufacturer of the equipment, operators should adhere to the least possible time between lubricants and should use premium multi-purpose heavy industrial lubricants. Besides, routine washing of the surfaces of equipment, filters, and ventilations can reduce the number of dust and residuals that build up on equipment and cause equipment to overheat or fail.

Preventive maintenance is maintenance work that is done on equipment at predetermined times as planned and not as the result of conveying some symptoms of needing maintenance work to be done on it. This technique helps to attend to important parts or elements in a machine before they finally give out thus preventing situations where a machine suddenly breaks down.

Scheduling of several periodic maintenance strategies should be done according to the individual requirements of the mineral processing equipment. For example, in magnetic disc separatorsNormal maintenance can comprise some particular procedures such as control of disc position, equilibrium degree of magnetic field, replacement of worn out magnets and so on. The concept of preventive maintenance is aimed at identifying potential problems before they become major catastrophes that could lead to the haltage of say an assembly line or any other production line as a result of equipment failure.

Yet another factor that is imperative towards sustainable maintenance of the mineral processing equipment is to make sure that the operators and the maintenance workers are well trained and knowledgeable about the equipment they are supposed to deal with. Staff familiarity as a positive argument is the fact that when the staff of a company is properly trained, it will be able to monitor the signs of equipment failure as well as carry out routine tasks better.

To avoid the problems affecting personnel, business organizations should ensure that their personnel attend refresher courses that will educate them on the current techniques and practices in the application of equipment as well as the new technologies available in the market. For instance, operators who use the magnetic disc separators need to understand the operational parameters of the particular device, how the settings may be changed in order to optimize the performance of the equipment and what problems might occur during the operation and how they can be solved. In the same vein with knowledge sharing to staff members, a culture of preventive maintenance is also promoted where staff members are keen on checking that all the equipment are in proper condition.

When finding replacement parts for mineral processing equipment, it is only wise to use OEM parts, and also to use high-quality tools. OEM parts are developed for the equipment they match perfectly since they are also produced by the same company and this is something that cannot be said about generic parts which are normally of very low quality and their use results in low efficiency, high breakdown rates and even potential hazards.

When servicing equipment such as the magnetic disc separators, it is recommended that magnets and other components other than those of the OEM are not used since this is likely to lead to either poor separation more so the equipment being damaged. Likewise, the right tools are used to guarantee that maintenance tasks are done in the right manner and without posing any risk to the workers. Some of the recommendations businesses should implement include deciding to go for genuine parts from an approved vendor and ensuring that the maintenance crew is equipped appropriately.

Mineral processing equipment must be well maintained in order to prevent the breakdown of the machines leading to very expensive downtime. A maintenance plan which includes periodic assessment of the equipment, regular greasing, carrying out preventive measures, staff education, and use of genuine parts from manufacturers are among the best strategies of managing equipment maintenance. For B2B companies they are not only effective in the longevity of the equipment used but also efficiency when it comes to maintenance costs.

Specialized equipment like for instance magnetic disc separators, need extra attention and frequent monitoring and maintenance to ensure the best performances. As outlined above, implementing these best practices assists business organizations to ensure the reliability of the mineral processing equipment, enhance the productivity of the operations and prevent the consequences that are associated with equipment failure.