If you’re in packaging, retail, or food service, chances are you’ve felt it: growing pressure to reduce plastic use, cut packaging waste, and show real commitment to sustainability. Governments are enforcing stricter bans on single-use plastics. Consumers are demanding eco-conscious brands. And businesses across the board are scrambling to adapt.

Paper bags have quickly re-emerged as a practical, planet-friendly solution. They’re biodegradable, recyclable, and easy to customize for different industries.

But meeting this demand isn’t just about switching materials—it’s about scaling production. And for that, more companies are turning to one tool that’s making a quiet but powerful impact: the paper bag making machine.

What Is a Paper Bag Making Machine?

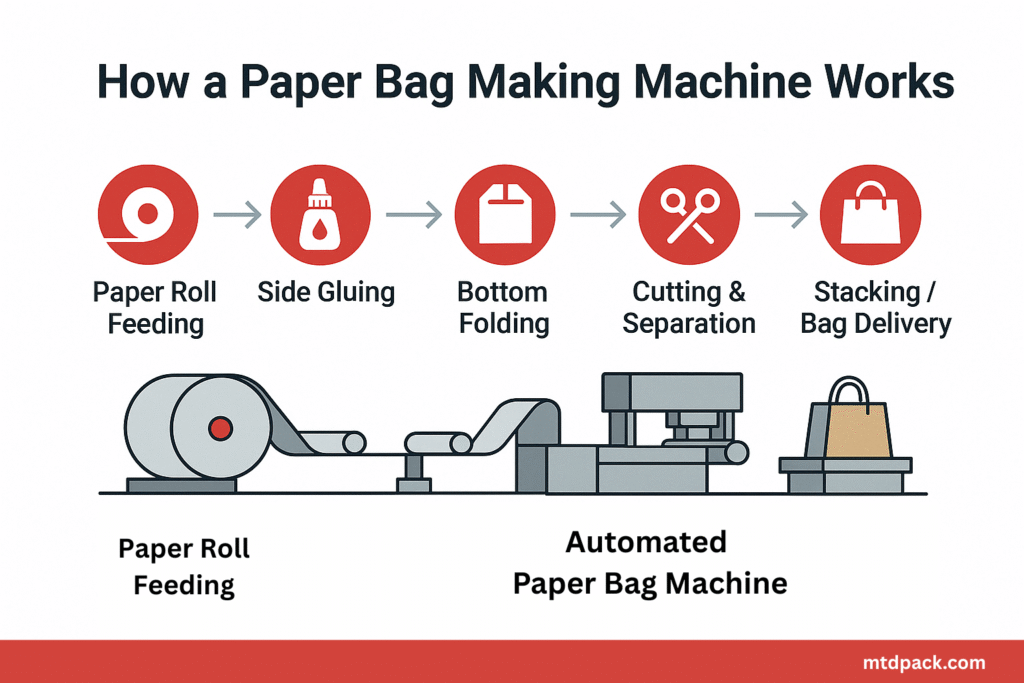

A paper bag making machine is an automated system designed to streamline the production of paper bags at scale. It performs key functions such as roll feeding, side gluing, bottom folding, bag cutting, and stacking—sometimes all in a single pass. This level of automation allows businesses to produce thousands of paper bags per hour with consistent quality and minimal waste.

Types of Paper Bag Machines

- Flat and satchel bag machines: Common in food service and retail

- Square bottom bag machines: Ideal for groceries, luxury packaging, and pharmacy bags

- Handle bag machines: Attach twisted or flat handles inline, suitable for premium retail

- Inline printing machines: Allow for custom branding or compliance labeling during production

A high-quality paper bag manufacturing machine often includes servo motors, PLC touchscreen controls, automatic tension adjustment, and sensor-based fault detection. These features not only improve operational stability but also reduce human error and downtime.

Modern machines are also designed to work with kraft paper, laminated sheets, or even food-grade paper—offering flexibility across industries.

Why More Brands Are Switching to Automated Paper Bag Production

Manual paper bag production has its place—but not for businesses trying to scale. As demand for eco-packaging continues to surge, many companies are hitting the limits of what hand-assembled operations can handle.

Automated systems like the modern paper bag machine offer a compelling solution by turning what was once a slow, labor-intensive process into a streamlined production line.

Key Benefits of Automation

Speed & Scalability

A commercial-grade paper bag machine can produce anywhere from 100 to 1000+ bags per minute. Compare that with manual folding and gluing, which might yield only a few hundred bags a day—and the productivity gains are clear.

Labor Savings

Fewer operators are required to run a machine, which lowers labor costs. Automation also reduces the risks of repetitive motion injuries and operator fatigue—common issues in manual assembly lines.

Consistency & Quality Control

Sensor-based systems detect misfeeds, improper gluing, or misalignment in real-time—ensuring consistent bag quality.

Lower Material Waste

Precise control over cutting and gluing mechanisms means minimal defective products and significantly less paper waste.

Automation and Sustainability: A Powerful Match

Choosing paper bags over plastic is already a sustainable step—but how those bags are produced can make an even bigger impact. An efficient paper bag making machine supports your brand’s environmental goals at every stage of production.

Sustainability Features to Look For

Energy Efficiency

Machines equipped with servo motors and idle power-saving modes cut down on electricity usage and emissions.

Precision Manufacturing

Less wasted paper and fewer misprints through smart tension control and auto-alignment systems.

Eco-Compatible Materials

The best machines support recycled and FSC-certified paper, water-based inks, and food-safe adhesives—helping meet environmental certifications.

Compliance Made Easy

From plastic bans to eco-labeling rules, automation helps businesses stay compliant while keeping operations lean.

In short, going green at scale is easier—and more cost-effective—when sustainability is built into the manufacturing process.

How to Choose the Right Paper Bag Machine for Your Business

Whether you’re running a local packaging facility or supplying bags to multinational retailers, the right equipment can make or break your operations.

What to Consider When Buying

Bag Type & Style

Start by identifying the bag formats you need:

- Flat & satchel bags for quick service

- Square bottom bags for groceries or retail

- Bags with handles for premium experiences

Output Capacity

Do you need high-speed performance or flexibility? Machines range from entry-level to industrial scale, so match the speed to your daily production target.

Add-On Capabilities

Inline printing, window cut-outs, and handle pasting can enhance product value—look for modular systems that grow with your needs.

Operator Interface

Touchscreen controls, auto fault detection, and real-time diagnostics simplify operations and reduce downtime.

After-Sales Support

Don’t overlook the value of strong support. Choose a manufacturer who offers parts availability, training, and remote troubleshooting.

Selecting the right paper bag manufacturing machine isn’t just a technical choice—it’s a strategic one that impacts your productivity, compliance, and ability to deliver a consistent customer experience.

If you’re looking for a trusted supplier with over 25 years of industry experience, MTDPACK.com offers a wide range of fully automatic paper bag machines—designed for speed, reliability, and customization. Whether you need small-batch flexibility or industrial-grade output, MTED’s solutions are built to support your long-term growth.

Final Thoughts: The Future of Packaging Starts with Smarter Machines

Eco-friendly packaging isn’t just a trend—it’s quickly becoming the norm. From regulatory shifts to rising consumer expectations, brands today are expected to reduce their environmental footprint without sacrificing efficiency or quality.

Paper bags offer a sustainable alternative, but scaling production takes more than good intentions—it takes the right tools. A high-performance paper bag making machine empowers your business to meet demand, stay compliant, and lower production costs, all while supporting a cleaner planet.

And with modern machines offering features like inline printing, energy efficiency, and minimal waste, the benefits go far beyond just making bags—they elevate your brand’s reputation and long-term resilience.

If your team is exploring ways to modernize packaging operations or meet green compliance standards, now is the time to take a closer look at what a professional-grade paper bag machine can do for you.